If you prefer to always view the website in English, please click here.

Endesa customer service

Answer your questions about Endesa on this page or contact us if you do not find an answer.

Frequently Asked Questions

- Contact Contact

- Invoices Invoices

- Contracts Contracts

- Client Area and App Client Area and App

- Procedures Procedures

- Prices Prices

If you need to contact us, we have a number of contact channels so you can choose the one that best suits your needs:

Endesa Client Area

The best option to resolve any questions with your contracts or invoices, undertake your procedures easily and see all your information with a single click.

But if you need the help of an agent we put all our channels at your disposal:

Contracting

On this free phone we will help you to find the best tariff. Customer service is available at the following times: Mon-Fri 8am to 10pm | Sat-Sun 9am to 9pm.

EndesaClic

With VoIP technology you can use your PC, mobile phone or tablet to speak directly to Customer Services 24 hours a day, 7 days a week

Customer Support

Our Customer Service free phone is available 24 hours a day, 7 days a week. We can also assist you in Catalan and in English.

On our map of offices and service points you can find where the Endesa office closest to you is located. You can make either an appointment in person or an appointment by video call which will save you travel and have your queries resolved from the comfort of your home.

Here are some of the procedures you can undertake at an Endesa office:

- Make a new contract.

- Change the power

- Change the contract holder.

- Be assessed.

- Pay your bills.

By registering in the Client Area you can undertake your procedures online without having to go to your nearest Endesa office.

Endesa has an extensive network of offices all over Spain to provide in-person customer service. Requesting an appointment with Endesa is very easy:

- The first step is to find the office closest to your home. To do this, go to the Endesa website, in the "offices and service points" section.

- You can choose to activate the option "see offices with prior appointment" or "see only offices with video attention".

- Once you have selected your office, you should select the service you wish to consult.

- Choose the date and time that best suit you.

- And finally fill out the form with your personal details to book the appointment.

- Once the appointment has been booked, it can be easily modified or cancelled on the same website.

To make an enquiry about your Endesa bills is really very simple:

- Just go to your Client Area. Select the "Procedures" menu.

- In "We are here to help you" you will find the "Open enquiry" section where you can resolve incidents regarding our products or services.

From the "Open enquiry" section you can easily and comfortably notify us of any queries you may have about your contracts, your payments, your supply and other aspects with regard to your invoice.

If you do not find the reply that Endesa gave to your complaint satisfactory, we would like to inform you that you can submit a complaint form addressed to the consumer body corresponding your autonomous community or municipality.

On 7 September 2023, Decree 90/2023 of the Regional Government of the Canary Islands came into force, which regulates customer service services, their characteristics, the procedure for obtaining complaint forms and how they are administered. They are obtained through a QR Code, which is provided at the consumer's request to be downloaded on an electronic device. This code provides access to the form required to electronically submit the complaint form at the electronic headquarters of the Regional Government of the Canary Islands.

Our Customer Service telephone works 24 hours a day, 7 days a week. We can also assist you in Catalan and in English: 800 760 266.

If you are not yet an Endesa customer, you have a company and you are interested in contracting with us, we will be happy to advise you with tariffs that will adapt to your consumption and maximise your savings: 900 906 664

If you are a customer of e-Distribución, the Endesa group distributor, you can check the status of your electricity supply point. If you are not with the Endesa group, you can find the contact telephone number in the "breakdowns" section of your invoice.

We will give you the key information you require to understand the different concepts in your invoices.

Your Endesa electricity bill | Endesa.

Your Endesa gas bill | Endesa.

In your Client Area you will find all your bills for electricity, gas and/or maintenance services that you have contracted with us. They are organised automatically so you can check them quickly from anywhere with an Internet connection. This means you will always have all your invoices organised in one place and you can download them whenever you want.

You only need to be registered:

- If you have not registered yet, please fill in this short registration form.

- If you are already registered, you just need to log in to your Client Area.

Once inside your Client Area, you just need to select the "Invoices" section. There you will see all your bills, in chronological order, with their corresponding amount.

Digitalising your invoice is very easy, you just need to follow two simple steps:

- First you need to be registered and logged in. If you have not yet done so, you need to register.

- Once logged in, go to your Client Area and select "Procedures" in the top menu.

- Go to the payments and invoices section and click on "Manage digital invoicing". You can view and activate or deactivate digital invoicing whenever you want.

By switching to digital invoicing, you have access to exclusive advantages including the following:

- Swiftness: Your invoices will arrive by e-mail as soon as they are issued.

- More information: You will enjoy more detailed information about your bills and consumption.

- Control: You will know your consumption instantly.

- Savings: You will have access to customised savings tools.

- More ecological: Avoiding travel helps reduce CO2 emissions.

There are different ways of knowing how much energy you have consumed during a certain period of time:

- On your invoices and digital invoice: In the "Electricity consumption information" section you can see the accumulated consumption during the billing period that appears in your bill.

- On the Endesa Clients app: Where you can view your electricity consumption from any mobile device.

- In your Client Area: Where you can check your consumption and compare it with previous consumption periods.

If you have not received your bill yet, it may be due to a number of reasons:

The bill has not been issued

Depending on your contract, bills are issued once a month or once every two months. To find out whether it has been issued you can enter the "Invoices" section in your Client Area.

The bill has been issued

You can check to see if you have activated digital invoicing in the "Procedures" section in the "Payment and invoices" section in "Manage Digital Invoicing" in your Client Area, which is where you can also verify to which e-mail address they are being sent.

We have the wrong data for you

You can correct them in your profile in your Client Area.

The contract is not active

We only issue bills for active contracts.

This disagreement may be for a number of reasons:

If you do not agree with the consumption invoiced for excessive consumption, you are recommended to review your consumption for the previous year for the same dates. If the reading is estimated you can notify us of the actual reading for your meter. Under exceptional circumstances, several months' consumption may have been included in one bill.

Other reasons may be the following:

- Excessive contracted power that increases the fixed term in your bill.

- One or more of the discounts previously applied to your invoice may have expired.

- Charge for maintenance service.

In any case, you can always consult your current contract which you will find your Client Area.

To understand the reason for a charge in your bank account go to your Client Area, click on "Invoices" and you will see all the invoices that have been issued in your name.

If you have doubts about any item in your invoice, via this link we will explain all the data and where they come from.

Check to see if digital invoicing is active by going to your Client Area. Go to "Procedures" in the top menu, then to "Payment and invoices" and click on "Manage digital invoicing". Also check to see if the e-mail address is correct.

Check that your postal address is correct and up to date. To do this, access your Client Area Profile, select "Contact details" and check the postal address.

Bill payments at the bank counter and by transfer take 3 working days to take effect.

The acronym ATR stands for "Acceso de Terceros a la Red" (Third Party Access to the Network), and refers to the permission that the distributor grants to customers so they can access the network in the free market. It is a toll whose price is set by the corresponding Ministry. It is reviewed periodically and includes certain costs including transport and distribution.

If you would like to contract with Endesa, we will show you step by step how to do this easily, quickly and securely.

The first step in contracting your supplies with us is to use our tariff recommender to help find the tariff that is most suitable for you and your circumstances.

If you are already an Endesa customer, select "Yes" and enter the user data for your Client Area if you are already registered, the system will take care of the rest. If you are not yet registered in the Endesa Client Area, register now to obtain all the advantages.

If you are not yet an Endesa customer, you will have to select the "No" box and fill in the form with your data to be able to continue.

To formalise your contract, we will need the following information:

- Your personal data and an address for the supply or, failing that, the CUPS.

- Name of the retailer with which you have contracted the supply.

- You will need to select the power you need.

- To pay your bills by direct debit, enter your payment details, account number (20 digits), IBAN or BIC (if you are a foreigner), and other necessary information.

If together with your electricity or gas contract you contract additional maintenance services, we will ask you for the characteristics of the corresponding equipment.

Endesa has a system to compare electricity and gas tariffs, because our tariffs adapt to you and your circumstances. All you need to do is answer a few questions and we will then make you a customised recommendation. Or if you are already very clear about which tariff to choose, you can also take a look at our catalogue.

Choosing the power is essential for the electrical installation in your home to work properly, if it is not enough the "fuses may blow" and if it is too much, it will end up affecting your bill and you will be paying more than you need to at the end of the month. That is why we recommend that you use our power calculator and after following a few simple steps you will be able to see what the optimal power for your home should be.

When you contract with Endesa it opens up a very wide range of possibilities including the following:

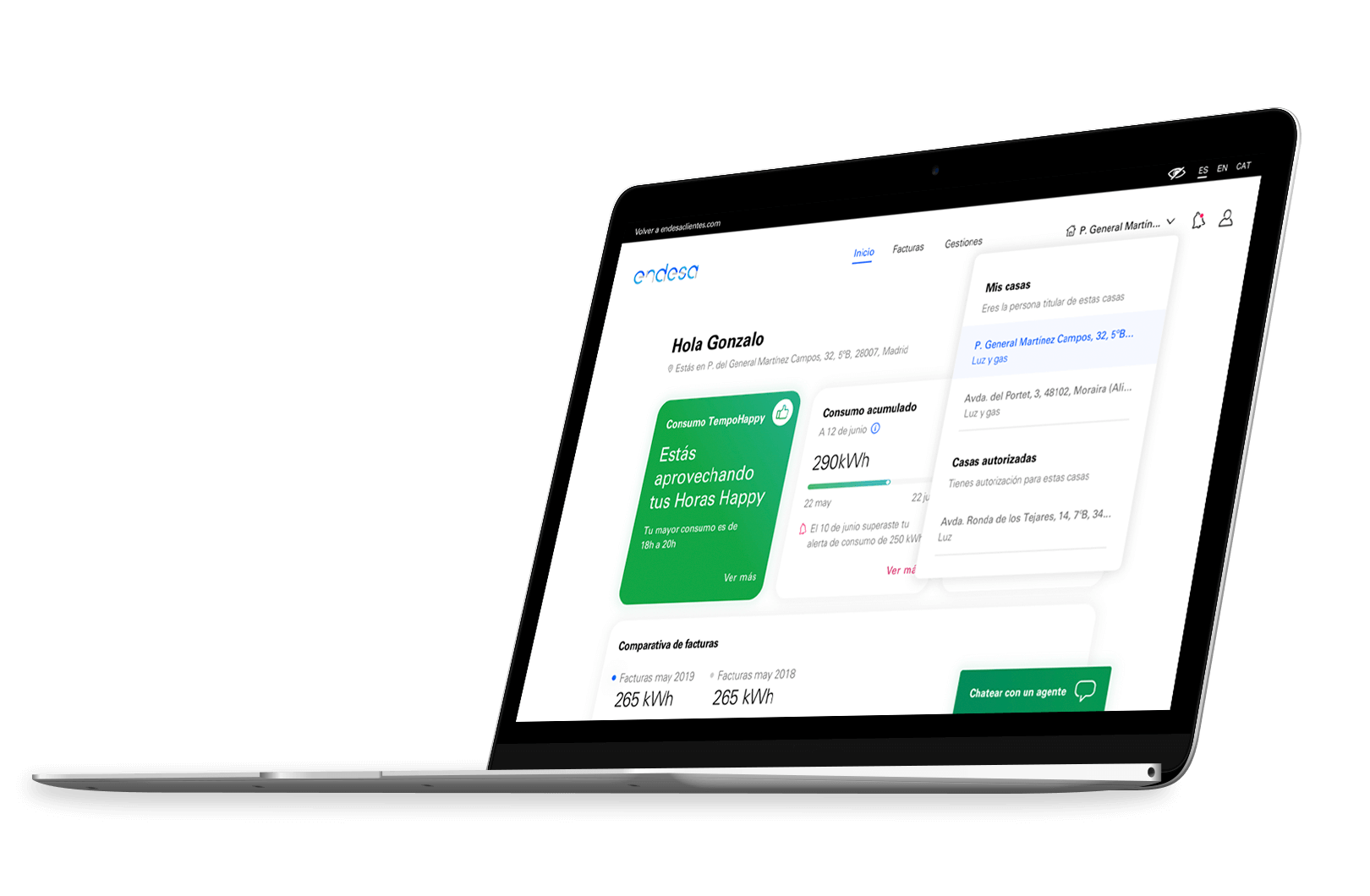

The Client Area and the Endesa Clients app

A made-to-measure space where you can manage your procedures and have absolute control of all your bills and consumption. All your information with just one click.

Exclusive advantages for Endesa customers

Just by being a customer, you will have customised offers and promotions at your fingertips. Worthy of the most exclusive club.

Our Customer Service

Personal, easy and fast customer service. We are with you from anywhere and whenever you want.

You only need to register if there is no electricity supply so if there is no supply it will be for one of the following reasons:

- A new building for which there has never been an electricity supply.

- A second-hand home or business premises that already had an electricity supply point registered but it was cancelled.

It is important to bear in mind that a new registration is completely different from a change of retailer, a change of tariff or a change of contract holder.

To be able to register you need to pay the electricity distributor.

You will need the following documentation:

- Address of the home or premises.

- The CUPS

- Electrical Installation Certificate or Bulletin

- Contract holder.

- The power for which you wish to register.

- Then IBAN number for the bank account to pay the bills by direct debit.

Endesa takes care of everything: Make a request for connection to the distribution network and register your contract, both at the same time.

You only need to register if there is no gas supply so if there is no supply it will be for one of the following reasons:

- New construction.

- A second-hand home or business premises that already had a gas supply point registered but it was cancelled.

It is important top remember that a new registration is completely different from a change of retailer, a change of tariff or a change of contract holder.

To be able to register you need to pay the gas distributor.

You will need the following documentation:

- Make sure that the indoor installation is ready to be connected, including the boiler or heater.

- The gas connection should be ready.

- Obtain a Gas Installation Certificate (C.I.G).

- You should have a CUPS.

- You should be clear with regard to the name, DNI/NIE and contact details of who will be the contract holder, as well as the bank account for the direct debits.

Once you have completed these 5 steps, all you need to do is call us and Endesa will process your gas service registration: 91 910 26 15

What Endesa offers tenants

- To know how much you consume each hour of each day, so if you change your habits it costs you less.

- Special tariffs with hours when consumption is free, assessment on the hours that may suit you best.

- Maintenance insurance so you do not depend on the landlord in the event of breakdowns, with urgent attention 24 hours a day, 7 days a week.

What Endesa offers owners

- No debts: You can supervise to see that the tenant leaves without owing anything.

- Tariffs that adapt to the tenant's consumption profile and that can be changed quickly and free of charge.

- You will have control over all your electricity/gas contracts and you will be able to see them in an orderly manner, with no confusion.

- You will understand at all times the house/premises that you are managing and the status of your invoices.

You will find more information about this below.

The acronym IEC corresponds to the "Certificado de Instalación Eléctrica" (Electrical Installation Certificate). This is also know as the "Electrical Bulletin" which certifies that the electrical installation is in good condition and that it meets technical requirements. It is an obligatory document for all homes, both newly built and second-hand.

The CUPS is the Universal Supply Point Code. It is a 20- or 22-alphanumeric digit code that in Spain begins with ES. Its purpose is to identify each home or business that receives energy, it is a form of ID. It is a unique, permanent and invariable code.

It is important that you know where to find it (on any of your electricity or gas bills next to the name of the contract holder) since you may need it to undertake some procedures such as registering for electricity, changing the retailer or changing the contracted power.

Cancelling is not the same as withdrawing from a contract. Withdrawing from a contract means that if you change your mind you have 14 days to cancel this request so that it does not take effect.

The Endesa Client Area is the equivalent of our online office. All your information will be organised, so you can easily access it from the comfort of your home.

We will show you the steps to follow so you can register:

- Click on the link below to access the registration form.

- Have the following information handy: Personal ID (DNI), e-mail address, mobile telephone number, contract and bank account.

- Add a new password to access your account.

- Check your phone number, to which we will send an SMS with the verification data.

- Once you receive the SMS, enter the code in the box ticked.

- You will receive an e-mail to confirm registration. If you do not see this e-mail in your inbox, please check in your spam and notifications folder.

- Activate your account via the link provided in the e-mail and then you will be able to access your Client Area account with your username and password.

The Client Area has a broad range of advantages, since it enables you to have all the information on your contracts and procedures with just one click. All in the same place, with no complications.

- You will be able to view all your energy in one place.

- View your expenses and consumption.

- Pay your bills online.

- Update your contact details.

- Change the power or the contract holder.

- Activate digital invoicing.

- Request customised assistance

And so much more!

You will also have your energy in your pocket if you download the free Endesa Client mobile app, which incorporates all the advantages of the Client Area.

The Endesa Clients app is the free, fast and easy-to-use application that we put at your service to enable you to manage your electricity and gas contracts, check your bills wherever you are and get information on our exclusive offers.

With Endesa Clients you can do the following:

- Know how much you are consuming every hour of every day.

- Have totally secure access with a fingerprint reader and facial recognition.

- Manage contracts and view invoices practically and directly.

- Pay outstanding bills using your mobile phone.

- Access customised assessment anytime you need it.

- Receive your invoices quickly via notifications to your mobile phone.

- Keep up to date with exclusive offers and the best promotions.

With Endesa your energy is unified in a single account with the same username and password. In your Client Area you can see what you consume and when you consume it, as well as how to undertake online procedures quickly and easily.

If you find it useful, you can also give permission to the people you choose so they can view invoices, download them and pay them. For example:

- Give permission to other household members or other family members who need support to undertake procedures and make payments.

- In landlord/tenant relationships: So both parties have all the information they need about the bills issued.

The people you authorise will also be able to see all the contract data and enquiries/complaints, as well as submitting gas meter readings.

If you need to recover your password to access the Client Area there is no need to worry, you just need to follow these simple steps:

- Go to Endesa's password recovery page by clicking on this link.

- Enter the e-mail address you used to register.

- Tick the “I am not a robot” box and click on the “Confirm” button.

- You will receive an e-mail with instructions on how to reset your password.

- If you do not receive this e-mail correctly, don't forget to check your spam or notification folder.

We show you step by step how to activate alerts on the Endesa Clients app so we can automatically inform you about your consumption, your new bills and totally customised recommendations.

- Enter your username and password to log in to the Endesa App.

- Once there, go to the "Procedures" section.

- Select the "Configure Alerts" option.

- In this section you can easily configure the alerts you would like to receive on your mobile phone:

o To receive alerts about new invoices, you just need to activate the service by sliding the button.

o To activate notifications with regard to consumption in your home, select the corresponding option.

o To activate notifications with regard to our customised recommendations, just slide the button.

- Once you are ready, always remember to save the changes so that they will be activated correctly.

InfoEnergía is a free information and energy assessment service for the control and management of your electricity consumption.

With this service you will be able to do the following:

- Have comprehensive information about your electricity consumption.

- Verify the energy efficiency of your domestic appliances.

- Get customised assessment based on your profile and lifestyle.

- This will help you reduce your electricity consumption, and as a result, you will save on your bill.

You will be able to understand your energy consumption without technicalities or complications: How much will you save in euros if you replace your appliances with more efficient ones? All you need is an electricity contract with Endesa and a power of less than 15 kW.

The term "carbon footprint" refers to the amount of greenhouse gases that are discharged daily into the atmosphere.

Endesa would like to help you calculate your carbon footprint and understand the impact it has on the environment, because every little bit helps.

Our model focusses on the digital relationship you have with us, as well as the products you have contracted:

- Activate digital invoicing. With this small gesture you can contribute to reducing CO2 emissions.

- Please make use of the video customer service, instead of going in person to the office, so you generate less CO2 and become more sustainable.

- Take a look at our tariffs designed for accessibility to electric mobility.

- If you are also considering contracting solar panels, we will be happy to advise you throughout the process in our self-consumption section.

Before changing the holder of a contract there are 3 important things you should know:

- The change has to be requested by the new holder.

- The new holder becomes responsible for the invoices.

- Changing the holder is a cost-free procedure, but in some cases you may have to pay the distribution company, which may decide that they need to inspect your installation and send a technician.

To make the change, you just need to call us at our free phone number (800 760 909) and have the following information ready:

- Details of the new contract holder: Name, surname(s), ID and telephone.

- Details of the previous contract holder: Name, surname(s), ID.

- CUPS (Universal Supply Point Code) or full address.

- Copy of the deed for the house or the rental agreement (where necessary).

- Direct debit bank account number.

It is very important to assess that power required to cover the needs of your home. With the Endesa power calculator we provide you simply and free of charge with the information you need to calculate how many kW you really need.

The process to change the power is very simple:

- Log in to your Client Area.

- Go to the “Procedures” section in the top menu.

- In the “Tariffs and consumption” section click on “Change my contracted power”.

- Choose your desired contracted power and accept the Legal Terms and Conditions.

- Click on "Save changes".

Please remember the changing power procedure is not a free of charge: It costs about €9 to lower the power and about €46 for each kW you increase.

You can change the bank account to which we send the payment collections for your Endesa invoices whenever you need to. It is very easy and we will show you the steps to follow:

- Log in to your Client Area.

- Click on the "Procedures" section.

- In the "Payment and invoices" section, you will find the "Modify direct debits" section, where you can update your bank account for electricity and/or gas contracts.

- You can also access from your Profile, by clicking on the "Payment methods" section.

- Add a new bank account, and remember to save your changes.

The Social Bonus is regulated by the Government and aims to protect households considered vulnerable or severely vulnerable because of their social-economic conditions. To take advantage of the Social Bonus you must have the PVPC electricity tariff as the only electricity companies authorised to offer the Social Bonus are regulated market retailers, and a power equal to or less than ten kilowatts in your primary residence.

Applying for the Social Bonus is completely free of charge. You can apply for the Social Bonus if your income does not exceed certain levels, if you are a pensioner, a large family or a recipient of the Minimum Wage.

The documentation you will need to apply for the Social Bonus is the following:

- Social Bonus Form filled in and signed by the entire family unit.

- Photocopy of the NIF or NIE of the holder of the electricity supply point.

- The official family book or individual certification from the Civil Registry for each of the members of the family unit.

- Registration of residency certificate.

- Photocopy of an official large family certificate currently in force.

- Or a certificate issued by the Social Services of the competent body that accredits Special Circumstances.

It is important not to confuse a change of retailer (the company with which you have a contract and that sends you the invoices) with the registration of supply.

A change of electricity company is a quick and simple process, you only need to provide the following information:

- Full name and Tax ID no. of the person who will be the contract holder.

- Address of the supply point for which you wish to change the retailer.

- A bank account where your bills will be paid by direct debit.

- Telephone number and e-mail for contact.

There is no need to worry about anything else because we manage all the procedures for the change completely free of charge and you will not be without electricity or gas for a single day.

You can change the postal address where we send your Endesa invoices whenever you need to. Changing the address for your invoices is a very simple procedure that you can do 100% online.

You just need to follow these simple steps:

- Log in to your Client Area. To do this, you first need to be registered.

- Click on your Profile in the right corner of your screen.

- Go to the "Contact details" section.

- In this section, you can change your postal address. Once you have made the change, please remember to save your data before leaving.

It takes a maximum of 1 month for your contract to become active after you register. You can check whether your contract is active by going to your Client Area.

For the cancellation of a contract to become effective, you should not have any unpaid invoices or have a contract modification in progress.

You have 1 month to cancel after your request to do so. You can lodge a complaint if your contract is still active after this time has elapsed. We will get back to you within 15 working days.

If 1 month has passed since your request and the change of holder has not yet been completed you can lodge a complaint. We will get back to you within 15 working days.

Once you request the change, we have ten working days to implement it. We will get back to you within 15 working days.

To change your bank account, go to the "Procedures" section, which is located at the top of the Client Area. Then, go to the "Payment and invoices" section, where you will find "Modify your direct debits".

When you make a change, we will respond within a maximum of 15 working days.

To check the tariff you have contracted go to your Client Area and then to the "Contract" section on your Home Page screen, where you can see your current tariff, the name of the holder and the contract number.

To modify your tariff, click on "Procedures", and in "Tariffs and consumption" you will be able to "Modify your Electricity or Gas tariffs".

It is important to remember that requesting termination implies the cessation of the supply, so the house or premises will no longer be supplied with electricity or gas. Therefore we recommend that you carefully consider what terminating supply entails.

The cancellation process is free of charge. It is requested and the supply point becomes inactive. If the home or premises is going to have a new tenant, we advise you to change the contract holder.

Termination may only be requested by the contract holder. In the event of death of the contract holder, consult the content on how to cancel a service after someone has passed away.

You can cancel a contract with Endesa from your Private Client Area, go to “Procedures”, “We are here to help” and click on “Terminate a supply”. Or call our freephone number 800 76 09 09.

The contract for inspection and/or repair services is annual, regardless of the periodicity of payment. There are two types of cancellation: If you have not used the service during the current year, the cancellation will be executed immediately. If you have used the service during the current year, the cancellation is scheduled for the same day that the annuity expires.

Please remember that termination can only be requested by the contract holder. This can be done through our free phone number 900 90 90 57.

In Spain, the price of energy on the wholesale market varies daily and is calculated in euros per megawatt hour (€/MWh). This wholesale price does not apply uniformly to all consumers, as it depends on the tariff they have contracted.

On 1 October last year, the VAT on natural gas was reduced from 21% to 5% temporarily and extraordinarily. The main objective of this measure is to alleviate the rise in prices and will be extended until 31 December 2023.

Toll tariffs are a part of your bill and they are used to pay what it costs for electricity and gas to reach your home. They are also called access tariffs.

- Electricity toll tariffs: In force since 1 June 2021. With new electricity time bands that affected the price and new names for access tariffs (tariffs 2.0 and 2.1 are now called 2.0TD). See our content on the new electricity tariffs.

- Gas toll tariffs: In force since 1 October 2021. With new annual consumption limits that determine which is your toll and new names for access tariffs (tariff 3.2 is separated into tariff RL.2 and RL.3). See our content on the new gas access tariffs.

The power term is the price you pay for the power contracted for your installation. This is a fixed cost, since it does not depend on the energy consumption you make and depending on your home you will need more or less.

If in your home you use a large number of appliances that need a lot of power to operate and you usually use them simultaneously, your power term should be higher than another home where there are few, small appliances that are not used regularly. If your power term is less than what you need, the "fuses will blow".